Lift Station Pumping and Maintenance: Expert Guide

Lift station pumping and maintenance guide: Optimize sewage systems, prevent failures, and wastewater management. Expert tips and schedules.

Lift station pumping and maintenance are essential for homes and businesses that rely on wastewater management systems. Timely and regular upkeep ensures efficiency, minimizes malfunctions, and prolongs the lifespan of these critical components.

Table of Contents

Key Takeaway

- Lift stations are crucial for pumping wastewater from lower to higher elevations.

- Regular maintenance helps prevent blockages, mechanical failures, and environmental hazards.

- Proper care includes routine inspections, component checks, and emergency protocols.

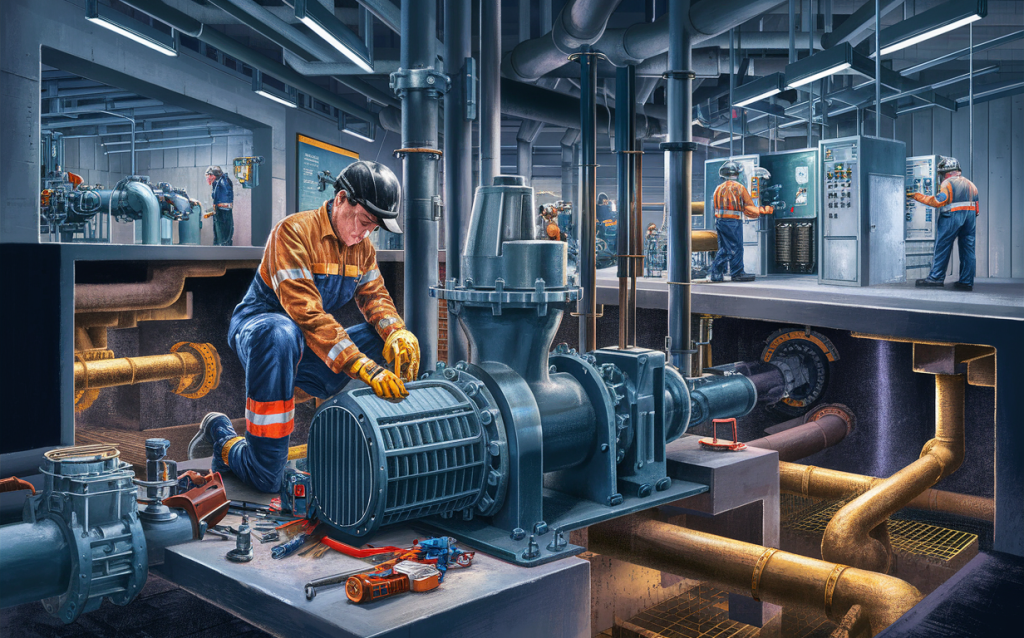

Understanding Lift Stations

Lift stations play a vital role in wastewater management. They pump sewage from lower to higher elevations, making it possible for wastewater to flow through treatment plants. These stations are essential in areas where gravity alone cannot move sewage efficiently.

Components of a Lift Station

- Pumps: Heart of the lift station, responsible for moving wastewater.

- Control Panels: Manage the operations and ensure all components work together.

- Wet Wells: Storage chambers for sewage before it gets pumped.

- Alarm Systems: Notify of malfunctions or high water levels.

- Valves and Piping: Direct the flow of wastewater.

Importance of Regular Pumping

Regular pumping is crucial to keep the lift station functioning. It removes accumulated solids, prevents blockages, and ensures the station operates at peak efficiency. Failing to pump regularly can lead to backups, environmental hazards, and costly repairs.

Maintenance Checklist for Lift Stations

A well-maintained lift station ensures longevity and reliability. Here’s a checklist to keep your system in top shape:

- Weekly Inspections: Check for unusual noises, leaks, and operational issues.

- Monthly Tests: Verify alarm systems and control panels.

- Quarterly Pump Checks: Ensure pumps are free of blockages and operating correctly.

- Annual Maintenance: Comprehensive inspection and servicing of all components.

Suggested Maintenance Schedule

| Frequency | Tasks |

|---|---|

| Weekly | Visual inspections, noise and leak checks |

| Monthly | Alarm system and control panel tests |

| Quarterly | Pump inspections, cleaning of wet wells |

| Annually | Full system inspection, servicing of all components |

Common Issues and Solutions

Even with regular maintenance, Lift station pumping and maintenance can encounter problems. Here are some common issues and their solutions:

- Pump Failures: Caused by blockages or mechanical failures. Regular cleaning and inspections can prevent this.

- Electrical Issues: Faulty wiring or control panel malfunctions. Ensure regular testing and servicing of electrical components.

- Overflow: Often due to blockages or pump failures. Routine pumping and inspections help mitigate this risk.

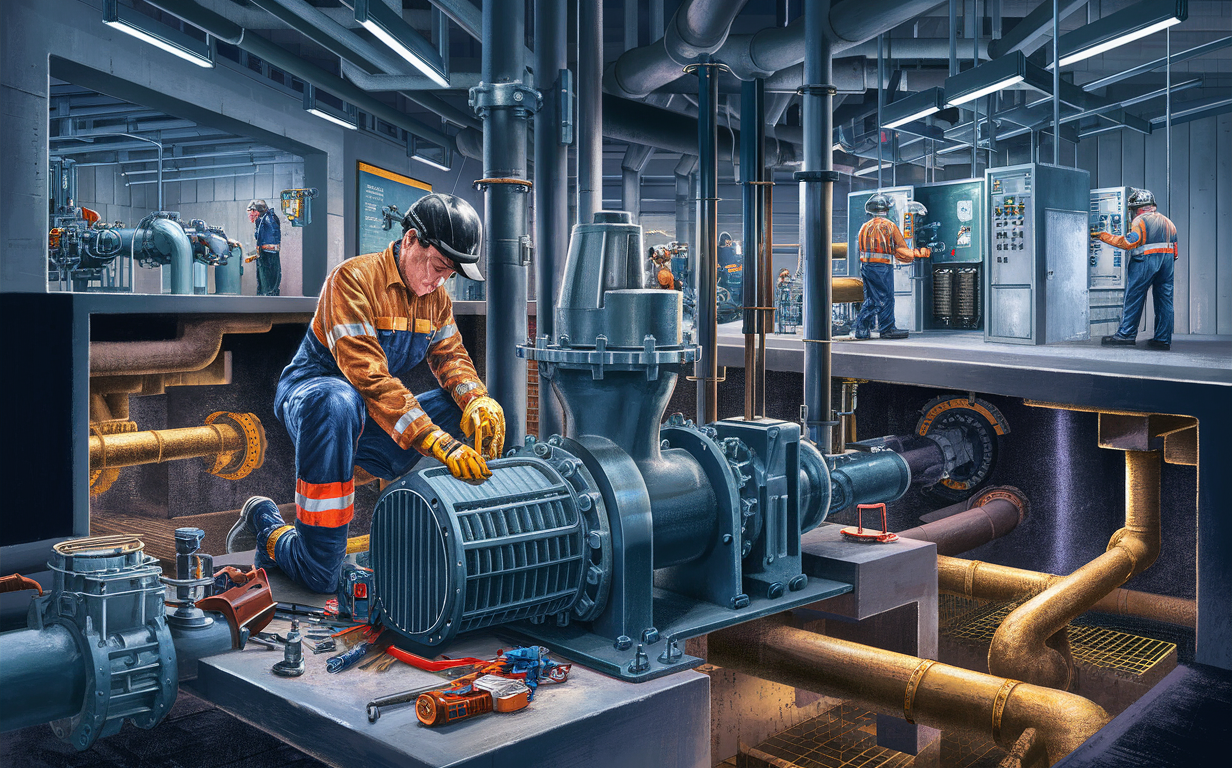

Preventive Measures

Preventive maintenance is the key to avoiding costly repairs and downtime. Here are some measures to keep your Lift station pumping and maintenance in optimal condition:

- Regular Cleaning: Prevents blockages and ensures smooth operation. Regular cleaning is essential for maintaining the efficiency and longevity of your equipment or systems. By routinely removing dust, debris, and any buildup, you not only prevent blockages that could disrupt the flow and performance but also minimize the risk of costly repairs and downtime. This proactive approach keeps everything running smoothly, reduces the strain on components, and extends the overall lifespan of your machinery.

- Component Checks: Ensures All Parts Are Functioning Correctly in Lift Station Pumping and Maintenance. Frequent checks on individual components are vital to the overall health of any system. By inspecting and testing each part regularly, you can identify wear and tear, detect potential issues early, and address them before they escalate into major problems. This routine assessment helps ensure that every component is operating as intended, thereby maintaining optimal performance and safety standards.

- Emergency Protocols: Emergency Protocols: Have a Plan in Place for Power Outages or Mechanical Failures in Lift Station Pumping and Maintenance. Have a plan in place for power outages or mechanical failures. Preparation for unexpected events is crucial in any operation. Establishing emergency protocols, such as detailed response plans for power outages or mechanical failures, ensures that everyone knows what to do when things go wrong. This planning not only helps to mitigate risks but also minimizes disruption and potential damage. By having a clear, practiced strategy in place, you can respond swiftly and effectively, safeguarding both your equipment and personnel.

Preventive Maintenance Measures

| Measure | Description |

|---|---|

| Regular Cleaning | Prevents blockages, ensures smooth operation |

| Component Checks | Ensures all parts are functioning correctly |

| Emergency Protocols | Plan for power outages or mechanical failures |

Technological Innovations in Lift Station Maintenance

Advancements in technology have made lift station maintenance more efficient. Here are some innovations:

- Remote Monitoring: Allows for real-time monitoring of lift station performance.

- Automatic Alarms: Notify immediately of any malfunctions.

- AI and Machine Learning: Predicts potential issues before they become major problems.

Emergency Response Protocols

Having an emergency response protocol is essential for immediate action in case of failures. Here are steps to include:

- Immediate Notification: Alarm systems should notify of any malfunctions.

- Quick Assessment: Determine the cause and extent of the problem.

- Rapid Response: Deploy a team to fix the issue promptly.

- Documentation: Record the incident and actions taken for future reference.

Emergency Response Steps

- Immediate Notification

- Quick Assessment

- Rapid Response

- Documentation

Sustainable Practices in Lift Station Maintenance

Sustainability is crucial in today’s world. Here are some practices to make lift station maintenance more eco-friendly:

- Energy-Efficient Pumps: Use pumps that consume less energy.

- Recycling Wastewater: Treat and reuse wastewater where possible.

- Biodegradable Cleaners: Use eco-friendly cleaning agents to minimize environmental impact.

Professional Services and Expertise

Hiring professional services ensures your lift station receives expert care. Here’s why you should consider professionals:

- Expertise: Professionals have the knowledge and experience to handle complex issues.

- Advanced Tools: Access to specialized tools and equipment for thorough maintenance.

- Compliance: Ensures your system adheres to local regulations and standards.

The Role of Regular Inspections

Regular inspections are crucial for the early detection of potential issues. Here’s what to look for:

- Pump Efficiency: Ensure pumps are working at full capacity.

- Electrical Systems: Check for any faults or malfunctions.

- Structural Integrity: Inspect wet wells and other structural components for any damage.

Conclusion

In summary, lift station pumping and maintenance are critical for efficient wastewater management. Regular upkeep ensures your system runs smoothly, prevents costly repairs, and minimizes environmental impact. By following a structured maintenance schedule and incorporating preventive measures, you can ensure the longevity and reliability of your lift station. Lift station pumping and maintenance guide: Optimize sewage systems, prevent failures, and wastewater management. Expert tips and schedules.

Contact Us

For professional lift station pumping and maintenance services, contact Texway Wastewater Services at (817) 889-4007 or visit our website. Our team of experts is ready to help you maintain a reliable and efficient wastewater management system.

Texway Wastewater Services is a septic, wastewater, and excavation company based out of Burleson, Texas and serving the surrounding areas. We specialize in

Texway Wastewater Services is a septic, wastewater, and excavation company based out of Burleson, Texas and serving the surrounding areas. We specialize in