Essential Grease Trap Pumping Services for Restaurants & Cafes

Grease trap pumping services are essential for maintaining the efficiency and longevity of commercial kitchens. Restaurants, cafes, and food service establishments rely heavily on these services to keep their operations running smoothly. Let’s dive into what grease trap pumping services entail and why they are crucial for your business.

Key Takeaway

- Grease trap pumping is necessary to prevent blockages and maintain compliance with health regulations.

- Regular maintenance ensures the longevity of your grease trap system.

- Professional services provide thorough cleaning and proper disposal of waste.

- Failure to maintain can lead to costly repairs and downtime.

What Are Grease Trap Pumping Services?

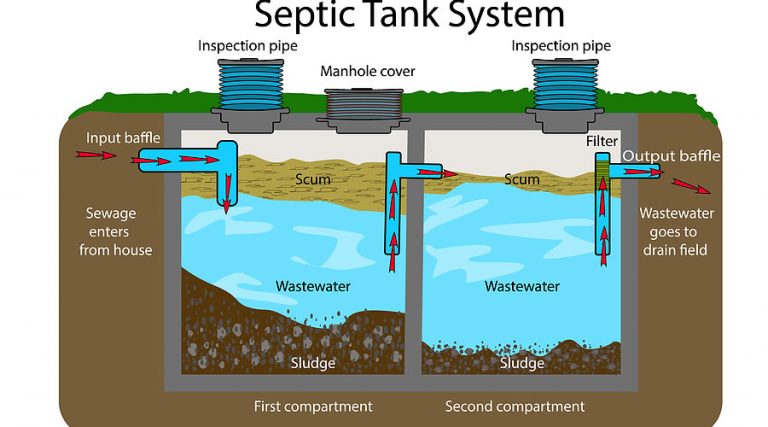

Grease trap pumping services involve the removal of accumulated fats, oils, and grease (FOG) from grease traps. These traps are designed to capture FOG before they enter the wastewater system, preventing blockages and environmental contamination.

Why Is Grease Trap Maintenance Important?

Regular grease trap maintenance is crucial for several reasons:

- Prevent Blockages: FOG can solidify and cause blockages in your plumbing system, leading to backups and costly repairs.

- Ensure Compliance: Health regulations require regular maintenance to prevent environmental contamination.

- Avoid Fines: Non-compliance with local regulations can result in hefty fines and legal issues.

- Extend Lifespan: Regular cleaning extends the life of your grease trap system, saving you money in the long run.

How Often Should You Pump Your Grease Trap?

The frequency of grease trap pumping depends on the size of the trap and the volume of FOG your establishment produces. However, a general guideline is to pump the grease trap every 1 to 3 months.

Factors Influencing Pumping Frequency

- Volume of Food Production: High-traffic kitchens require more frequent pumping.

- Size of Grease Trap: Larger traps can hold more FOG, allowing for less frequent pumping.

- Type of Food Served: Grease-heavy foods like fried items produce more FOG.

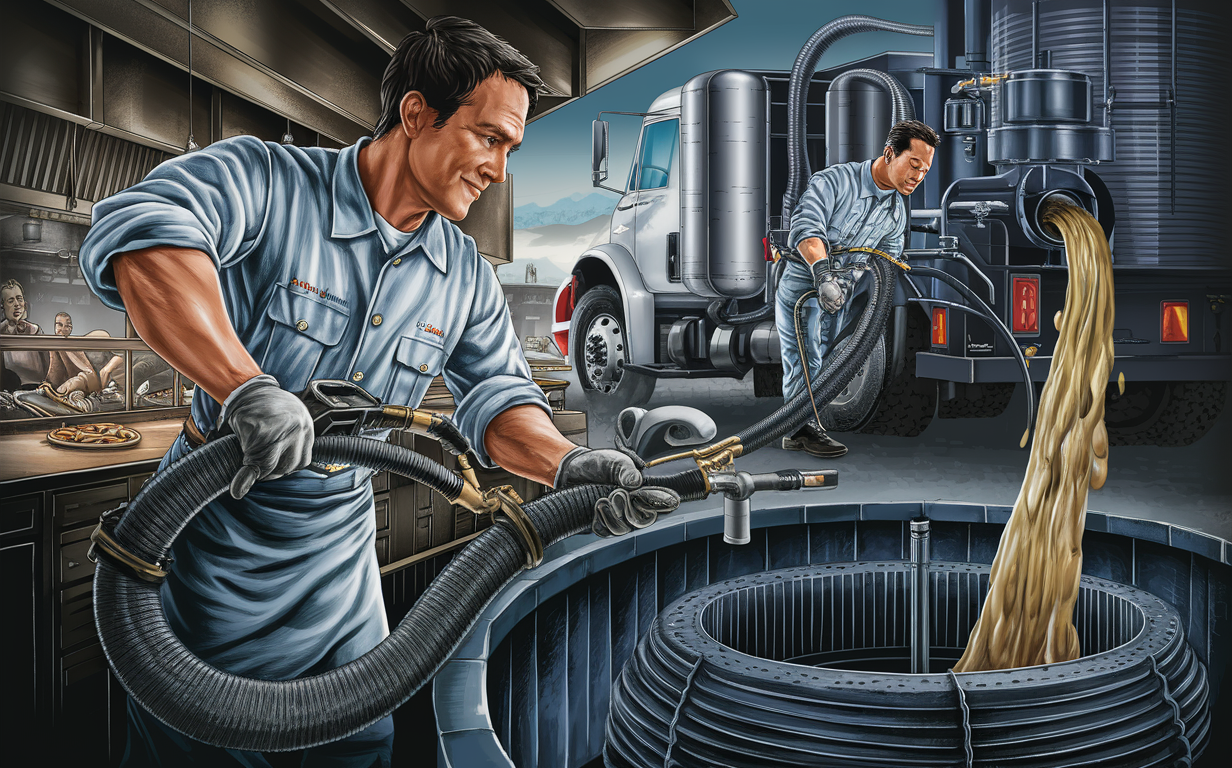

The Process of Grease Trap Pumping

Grease trap pumping involves several steps to ensure thorough cleaning and proper waste disposal.

- Inspection: A professional will inspect the grease trap to assess its condition.

- Pumping: Using specialized equipment, the accumulated FOG is pumped out.

- Scraping and Cleaning: The interior of the trap is scraped and cleaned to remove any residual grease.

- Disposal: The collected FOG is disposed of according to environmental regulations.

- Documentation: Proper documentation is provided to ensure compliance with local regulations.

Benefits of Professional Grease Trap Pumping Services

Hiring professional grease trap pumping services offers numerous benefits:

- Expertise: Professionals have the knowledge and equipment to perform thorough cleaning.

- Compliance: Ensure your establishment meets health and environmental standards.

- Efficiency: Save time and focus on running your business.

- Preventative Maintenance: Regular inspections can identify potential issues before they become major problems.

Professional vs. DIY Grease Trap Cleaning

| Aspect | Professional Service | DIY Cleaning |

|---|---|---|

| Expertise | Trained technicians with specialized equipment | Limited by personal knowledge and tools |

| Compliance | Guarantees compliance with local regulations | Risk of non-compliance and possible fines |

| Efficiency | Quick and thorough cleaning | Time-consuming and less thorough |

| Cost | Service fee but prevents costly repairs | Lower upfront cost but potential for expensive repairs |

| Safety | Safe handling and disposal of hazardous waste | Risk of improper waste handling |

Common Problems with Grease Traps

Grease traps can encounter various issues if not maintained properly. Here are some common problems:

- Blockages: Caused by solidified grease and food particles.

- Odors: Unpleasant smells from accumulated waste.

- Overflow: Due to infrequent pumping, leading to spillage.

- Corrosion: Grease and waste can corrode the trap’s interior over time.

How to Identify Grease Trap Problems

Identifying issues early can save you from costly repairs. Look out for these signs:

- Slow Draining: Indicates potential blockages.

- Foul Odors: Suggests accumulated waste.

- Frequent Backups: Points to an overfilled trap.

- Visible Grease: Grease discharge in your sink or dishwasher.

Tips for Maintaining Your Grease Trap System

Maintaining your grease trap system is essential for smooth operation. Follow these tips:

- Regular Pumping: Stick to a maintenance schedule.

- Proper Disposal: Dispose of kitchen waste responsibly.

- Use Grease Interceptors: Install interceptors to capture FOG before it reaches the trap.

- Educate Staff: Train staff on proper grease disposal practices.

List of Do’s and Don’ts for Grease Trap Maintenance

Do’s

- Schedule regular pumping services.

- Train staff on proper grease disposal.

- Install grease interceptors.

- Monitor the grease trap for signs of issues.

Don’ts

- Dump grease down the sink.

- Ignore foul odors or slow drains.

- Delay scheduled maintenance.

- Attempt DIY repairs without proper knowledge.

Innovations in Grease Trap Technology

The wastewater industry is continually evolving, and innovations in grease trap technology can enhance efficiency and compliance.

Advanced Grease Trap Systems

Modern grease traps offer features like:

- Automated Monitoring: Alerts for maintenance needs.

- Self-Cleaning: Reduces manual cleaning frequency.

- Remote Management: Allows remote monitoring and control.

Benefits of Upgrading Your Grease Trap System

- Increased Efficiency: Reduces manual intervention.

- Cost Savings: Lower maintenance and repair costs.

- Compliance Assurance: Stay ahead of regulatory requirements.

| Feature | Traditional Grease Trap | Advanced Grease Trap System |

|---|---|---|

| Maintenance | Manual and frequent | Automated and less frequent |

| Monitoring | Requires regular checks | Automated alerts and remote monitoring |

| Cleaning | Manual scraping and pumping | Self-cleaning mechanisms |

| Compliance | Risk of non-compliance | Ensured compliance with regulations |

| Cost | Higher long-term costs | Upfront investment but lower long-term costs |

- Market Size: The global grease trap market size was valued at USD 2.3 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028, according to a report by Grand View Research (source).

- Number of Establishments: In the US alone, there are approximately 660,000 restaurants and foodservice locations, according to the National Restaurant Association (source).

- Frequency of Pumping: Grease traps in restaurants and cafes should be pumped out every 3-6 months, according to the Environmental Protection Agency (EPA) (source).

- Cost: The average cost of grease trap pumping ranges from $150 to $400 per visit, according to HomeAdvisor (source).

- Benefits: Regular grease trap pumping can prevent sewer backups, reduce the risk of plumbing issues, and help maintain a clean and odor-free kitchen (source).

How to Choose the Right Grease Trap Pumping Service

Selecting the right grease trap pumping service is crucial for effective maintenance. Consider these factors:

Experience and Expertise

- Look for a service with a proven track record.

- Ensure they have experience with your type of establishment.

Licensing and Insurance

- Verify that the service is licensed and insured.

- This protects you from liability in case of accidents or damage.

Customer Reviews

- Read reviews from other businesses.

- Good feedback is a sign of reliable service.

Pricing

- Compare prices but don’t compromise on quality.

- Look for transparent pricing with no hidden fees.

Availability

- Choose a service that offers flexible scheduling.

- Emergency services are a plus for unexpected issues.

The Environmental Impact of Grease Trap Maintenance

Proper grease trap maintenance has a significant positive impact on the environment. It prevents FOG from entering the wastewater system, reducing pollution and protecting water quality.

Sustainability Practices

- Recycling FOG: Some services recycle collected FOG into biofuel.

- Proper Disposal: Ensures waste is disposed of according to environmental regulations.

- Education: Educating businesses on sustainable practices.

Conclusion

Grease trap pumping services are essential for maintaining the efficiency, compliance, and longevity of commercial kitchens. By hiring professional services, you ensure thorough cleaning, proper waste disposal, and adherence to health and environmental regulations.

Regular maintenance not only prevents costly repairs but also contributes to a sustainable and efficient operation. Choose a reliable service provider to keep your grease trap system in optimal condition and focus on what you do best – running your business.

Contact us today at (817) 889-4007 or schedule a service to your most convenient time.

Texway Wastewater Services is a septic, wastewater, and excavation company based out of Burleson, Texas and serving the surrounding areas. We specialize in

Texway Wastewater Services is a septic, wastewater, and excavation company based out of Burleson, Texas and serving the surrounding areas. We specialize in